Dot Peen Machines

HOME > PRODUCTS > DOT PEEN > DOT PEEN MACHINES

DOT PEEN MACHINES

TMP4500E

A powerful piece of handheld equipment, this dot peen marker eliminates the need for air. The TMP4500E makes deep marks and is easy to hold.

our products to your day-to-day operations provides:

Excellent traceability: Our dot peen markers deliver precise dot placement that yields high-quality marks.

Efficient marking process: We design our dot peen markers to complete jobs quickly and provide consistent output.

Improved durability: We manufacture markers with high-grade materials that stand up to various manufacturing challenges.

Wider scope of operations: Our floating pin technology uses stepper motors and precise pin locations that allow marking on both flat and irregular surfaces.

TMP4750

The TMP4750 is the latest addition to the PINSTAMP® family of marking systems.

The versatile TMP4750 boasts a rack and pinion platform delivering the most precise dot placement in the industry; this equates to clean crisp 2D codes every time. The 140mm x 40mm marking window makes an excellent choice for VIN marking. Available in both handheld and fixed mount versions, this marker fits nearly every dot pin application.

The Telesis PINSTAMP® Dot Peen machine is a proven industrial workhorse and industry staple that continues to impress. The rugged, low-maintenance X/Y platform has a compact and contaminant-resistant head design that can mark a wide range of materials from soft plastics to hardened steel (rc60). Interchangeable pin sizes create marking depths of 0.001 in – 0.018 in (0.03 mm – 0.45 mm) and the floating pin technology accommodates surface irregularities up to 0.25 in (6 mm).

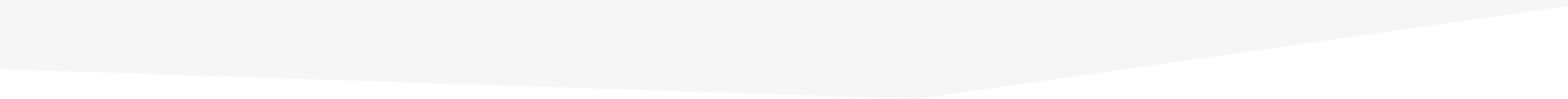

TMP3200

The TMP3200 is a simple, yet robust belt-driven, dual-rail system that uses an X/Y platform and yields high-quality characters.

The rugged design means a long-lasting, low maintenance operation while having the ability to mark a wide range of materials from soft plastics to hardened steel (rc60). The floating pin technology accommodates surface irregularities up to 0.25 in (6mm) easily and the generously sized marking window sets this dot peen marker apart from the rest.

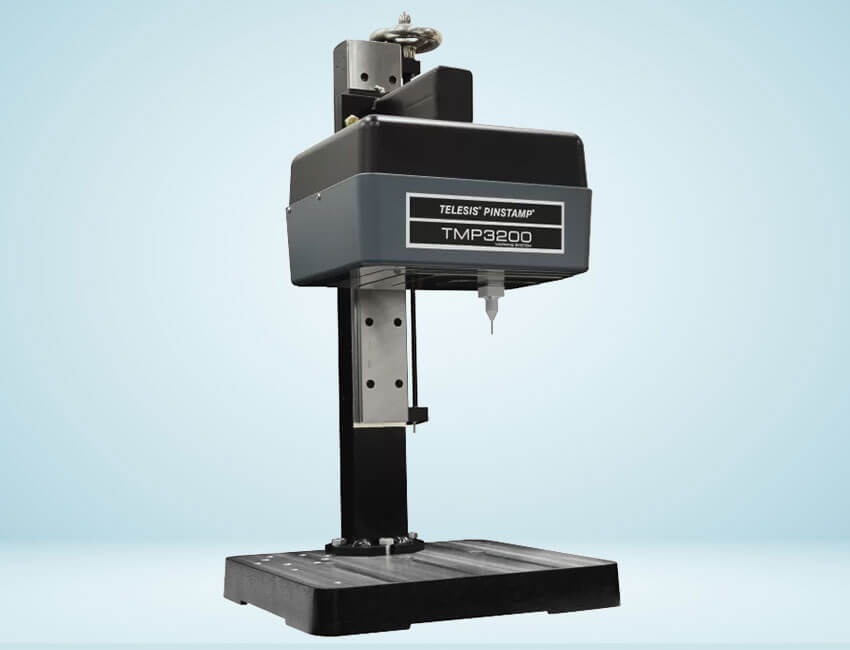

TMM5400

The PINSTAMP TMM5400 is a multi-pin dot peen marking system. The marker features 8 independent pins that allow it to make up to 16 characters per second.

The extremely compact marking head is also one of the world’s fastest dot peen markers. It achieves this by assigning a solenoid valve to each pin.

Telesis proprietary floating pin technology gives this dot peen marker superior power and speed. Compressed air replaces the need for springs, eliminating costly consumables. The marker can be fully integrated into a production line or used in a bench top fashion.

TMP6100

Great for cylindrical marking where a rotary device can add efficiency and practicality.

The TMP6100 is the most versatile PINSTAMP® automated dot peen marker, with durable components that can withstand tough manufacturing environments. Not only can it serve a wide range of marking applications, but it integrates seamlessly into factory automation networks.

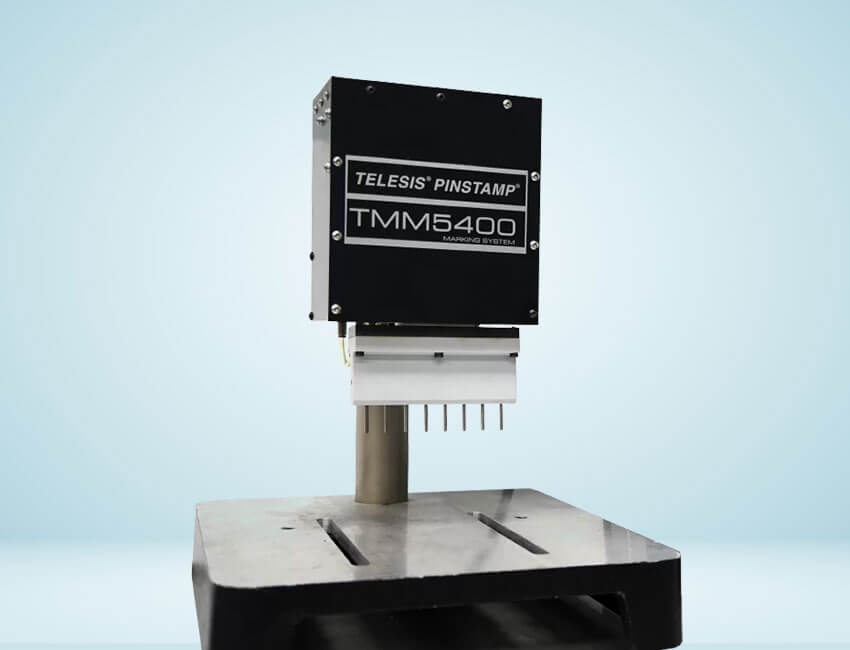

TMP1000

The TMP 1000/400 is the lowest cost PINSTAMP Marking System.The rugged TMP 1000 marking head features a compact window, and marking speeds up to six Characters per second. It”s an excellent choice for many factory automated or on line processes. The TMP 1000/400 includes the TMP 1000 Marking Head, but features our WIN 32 Merlin II Visual Design Software. Providing a state of the art graphical user interface.

Features

• Oil Resistant Fabric Boot

• Marking Head Extension Cables

• Foot Switch(Start Print) or Pushbutton Station(Start/Abort)

• Tool Post Assembly

• Auxiliary axis Driver Board Kit

• Motorized Z-Axis Tool Post with Programmable Travel

• Motorized Theta-axis with Programmable Roatry Driver Unit.

• 400 controller wall mounting Bracket kit

• 400 controller Panel-mounting Bezel/Bracket Kit

• 400 NEMA Enclosure

• Merlin II Visual Design Software

• System Computer (to run the Merlin II Software)

• 2D Code Capable Software

• Bar Code Scanner or Bar Code Wand with cable

• Backup Utility Software

• Upgrade Utility Software

• Logo/Front Generator Software

• Marks a wide range of materials from soft plastics to hardened steel-upto Rc60

• Shutter assembly protects marking head from solid and Liquid contaminants

• Dot density upto 200 dots per inch (79 per centimeter)

• Choice of interchangeable Marking Pin Types for depths from 0.001″ to 0.018″(0.03 mm to 0.45)

• Pin Travel accomodates surface irregularities to 6mm

• Automatically generates serial numbers,time,date,& shift codes.

• Easily interfaced to PLC”s (Programmable Logic Controllers) and Host Computers.

• Pin Materials:Carbide(10 MP-Series Micropin)Powdered metal or stainless steel with diamond tip or carbide(25L,25 XL Series).Powdered metal or tool steel with carbide tip (150S,150 SA-Series)

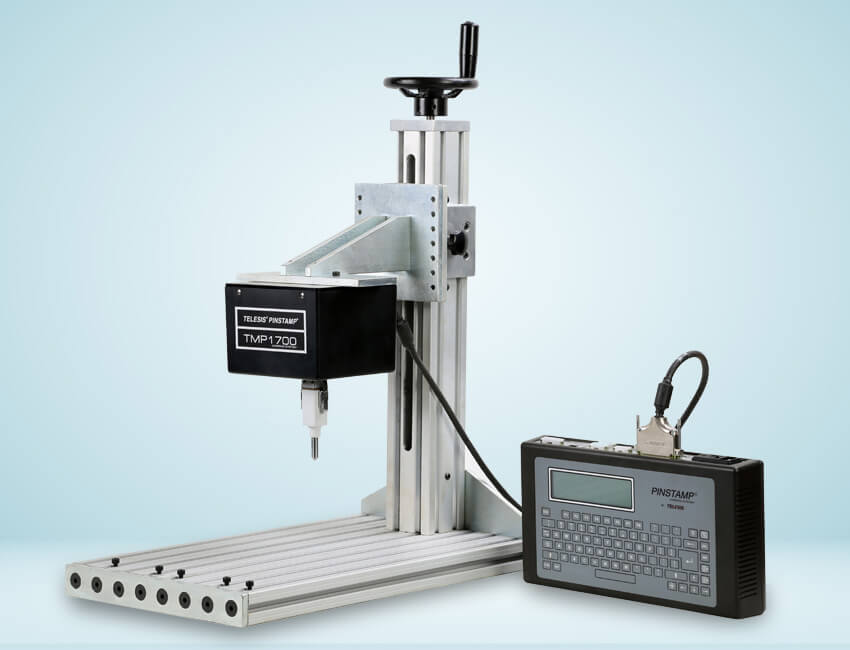

TMP1700 Dot Peen Machine

The Telesis TMP1700 pinstamp system is a dot peen marking machine designed for industrial applications. It’s known for its durability and ability to create precise, permanent marks on a variety of materials, including metals and plastics. The TMP1700 operates by pneumatically driving a hardened pin to indent dot matrix characters into the item being marked. Users can control the shape, size, density, and location of characters through the system’s software, which also allows for the automatic generation of serial numbers, time, date, and shift codes. The Telesis TMP1700’s floating pin technology can accommodate surface irregularities up to 0.25 inches, ensuring consistent marking quality even on irregular surfaces. With interchangeable pin sizes, it offers marking depths from 0.001 inches to 0.018 inches. The Telesis TMP1700 pinstamp system is designed to be low-maintenance and is paired with the touchscreen controller, making it one of the most advanced dot peen markers in the industry.

TMP7000

The TMP7000 Marking Head includes the mechanical motion components to position the marking pin at precise X/Y positions and the pneumatic components to drive the marking pin out from, and return the pin back into, the pin cartridge. The TMP7000 marking head is an X/Y-traversing mechanism. Using two stepper motor drives, it accurately and rapidly positions the pin at coordinate-defined locations in marking window within .001in. (.025 mm). The TMP7000 accommodates the rigorous and rapid positioning of the marking pin through a system of rigid rails and ball bearing saddles, timing belts, and direct-drive, toothed pulleys. The floating pin design permits high quality, consistent marks on irregular, slightly curved surfaces. It also accommodates applications where marking surfaces cannot be positioned at a consistent distance from the marker

CONTACT US

Further if you have any specific or customizable requirements, we’re here to assist you!

Fill up the form or connect with us at sales@forbes.co.in

We create solutions that work for you!